Pioneering Research Paves Way for Greener Aerospace and Automotive Industries

In a significant breakthrough, a team of researchers has developed a game-changing hybrid nanofiller that is set to revolutionize the machining of carbon fiber-reinforced plastics (CFRPs). This innovation has far-reaching implications for the aerospace and automotive industries, which heavily rely on CFRPs for their lightweight and high-strength properties.

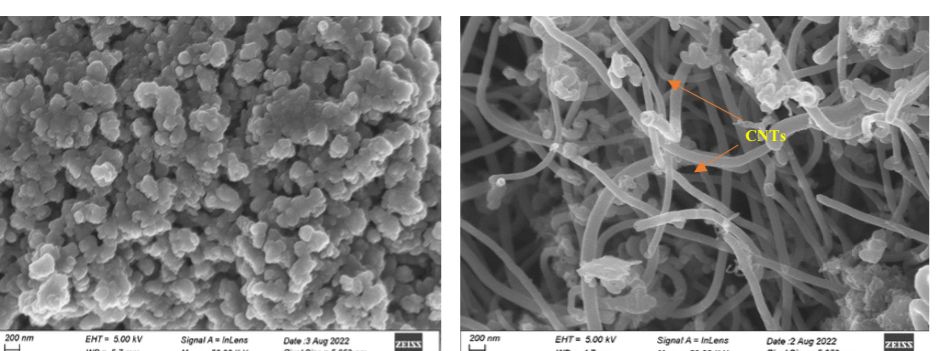

The novel nanofiller, composed of carbon nanotubes (CNTs) and green titania (TiO₂), boasts exceptional stability, surface area, and heat dissipation capabilities. This makes it an ideal solution for use in nanofluids during CFRP machining, enabling industries to reduce their environmental footprint while maintaining high-performance standards.

The aerospace and automotive industries are among the largest consumers of CFRPs, using them in a wide range of applications, from aircraft and car bodies to engine components. However, the machining of CFRPs has long been a challenge due to the high levels of heat generated during the process, which can lead to damage and reduce the lifespan of the materials.

The development of this hybrid nanofiller addresses this challenge head-on, providing a sustainable solution that reduces environmental pollution, enhances machining quality, and minimizes coolant usage. This breakthrough has the potential to transform the manufacturing processes of the aerospace and automotive industries, enabling them to adopt more sustainable practices while maintaining their competitive edge.

As the world continues to shift towards more sustainable practices, this innovation is poised to play a vital role in reducing the environmental footprint of these industries. With its potential to revolutionize the machining of CFRPs, this pioneering research is set to have a lasting impact on the future of sustainable manufacturing.