Breakthrough in Sustainable Machining: Researchers Develop Eco-Friendly Nanofillers.

In a significant step towards sustainable manufacturing, researchers have successfully developed a hybrid nanofiller made from carbon nanotubes (CNTs) and green titania (TiO₂). This innovative material is designed for use in nanofluids during the machining of carbon fiber-reinforced plastics (CFRPs), a crucial process in various industries.

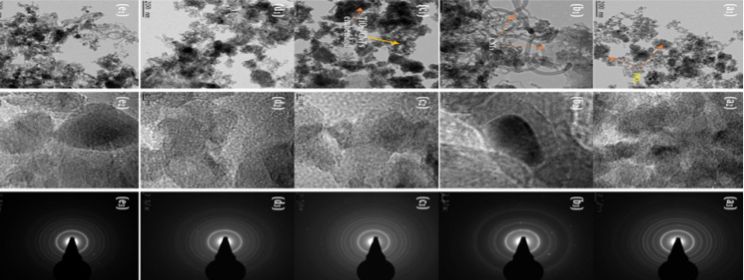

The research team synthesized and characterized TiO₂/CNT nanocomposites in various ratios, ultimately identifying the 5:5 ratio as the optimal composition. This breakthrough nanofiller boasts superior stability, surface area, and heat dissipation capabilities, addressing long-standing challenges in machining.

According to the researchers, this eco-friendly nanofiller promotes sustainable manufacturing by reducing environmental pollution, enhancing machining quality, and minimizing coolant usage. This achievement aligns with the United Nations' Sustainable Development Goal #12, which emphasizes responsible production and consumption practices.

The development of this hybrid nanofiller is expected to have far-reaching implications for industries relying on CFRP machining, such as aerospace, automotive, and renewable energy. As the world shifts towards more sustainable practices, this innovation is poised to play a vital role in reducing the environmental footprint of manufacturing processes.

With this groundbreaking achievement, the research team has paved the way for the development of green, high-performance machining solutions, marking a significant step towards a more sustainable future.